Search Results for: selection criteria examples i work for nsw customer service

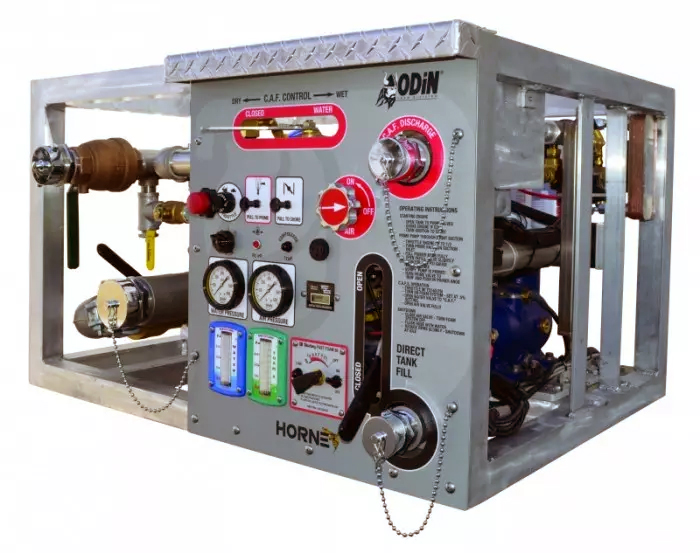

This model provides a “self-contained” gasoline-powered “slide-in” type Compressed Air Foam System (CAFS). The CAFS is designed to fit into the back of a standard length and width pick-up truck or fire service body.

The CAFS is designed to discharge water only, air only, foam solution only, or compressed air foam from the same discharge outlet. In addition, the consistency of the compressed air foam (expansion ratio), wet/dry, is fully adjustable.

Connect to a hydrant or pressurized supply, and the AutoFill™ valve direct tank fill system does the rest. It maintains the water tank level without any operator assistance. To increase the safety of firefighter personnel, the apparatus shall be equipped with an automatic direct tank fill system. The system shall operate refilling operations independently, without monitoring by the engineer. Refill operation shall not require apparatus or fire pump to be running. The system shall be capable of handling pressurized sources up to 300 psi. The AutoFill system gets an electronic signal from a Fire Research Vision Series water level gauge (REQUIRED). The water level gauge supplies a programmed signal to stop filling when the tank level is at 85% full and resume filling when the tank level reaches 50%. The valve system shall be able to be manually overridden in case of electric failure.

The air compressor must be designed to be installed on the apparatus chassis and have a 100% duty cycle. The air compressor shall be an American manufactured, continuous duty, oil-injected type, rotary screw rated up to 150 cfm @ 150 psi. Parts shall be readily available and stocked in the USA with certified service centers in all 50 states. It shall have an additional speed-up gearbox designed and integrally built by the compressor manufacturer. Compressor to have side-by-side gear set to provide for maximum ground clearance. A copy of the certification record shall be included.

The air receiver/separator (vessel) must act as an air/oil separator. The vessel shall be powder-coated carbon steel material and contain an integrated coalescing oil separator element. The vessel must have a lubricant sight glass no smaller than 2” in diameter. The pressure vessel must have a 200 psi (13.8 b) high-pressure relief valve. The vessel must have a replaceable spin-on 25-micron oil filter with safety bypass feature. It must contain an integral, pneumatically piloted blow-down valve. The vessel shall be a horizontal mount design. (A vertical mount air/oil receiver is available as an option.) The vessel shall meet all vessel ASME requirements. Oil carryover is rated 10 ppm or under at full flow.

The ATP FOAM FLURRY™ is our most economical proportioner. It is simple to install and operate and works without 12v power – no amperage issues for small pumps. For your next Darley portable pump purchase or retrofitting your current pump, the ATP FOAM FLURRY™ will deliver foam cost-effectively.

- All brass construction – no plastic

- Fast adjusting variable control ball valve

- Capable of .5% injection rate up to 130 gpm

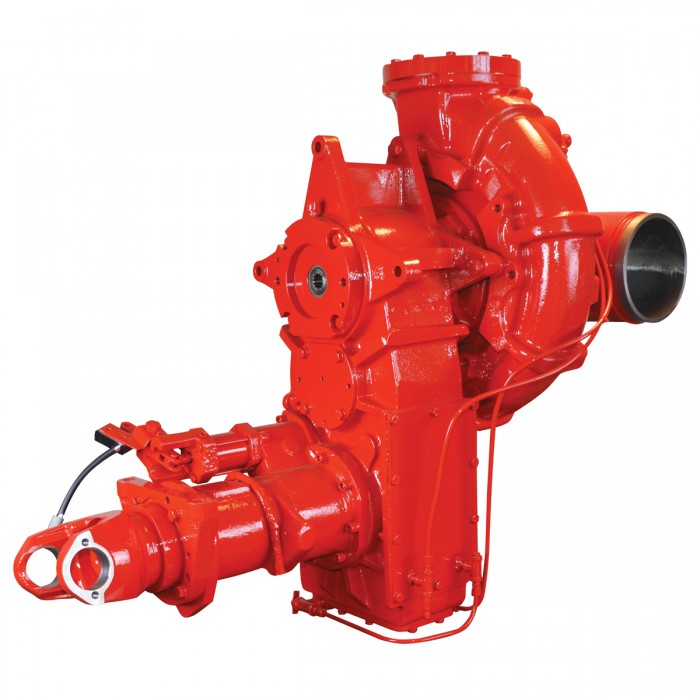

Centrifugal, Single Suction Impeller

The Darley PSM 2000 GPM pump is the most compact, durable, and efficient 2000 GPM pump on the market. The PSM Pump is NFPA can be rated from 1000 to 2000 GPM and is capable of flows well over 2200 GPM.

Designed by experts in fluid dynamics technology, the PSM utilizes the industry’s best silicon carbide mechanical seals, which is an extremely hard and heat dissipative material, resisting wear and dry running damage much better than conventional Ni-resist and Tungsten Carbide materials and has optional discharge check valve allowing for fast priming.

The gearbox is rated to handle 19,230 ft. lbs. of torque, and gears are helically cut to ensure quiet operation. The impeller is vacuum cast, eliminating porosity, and dynamically balanced to ensure smooth operation while spinning at over 4000 RPM.

Pumps are modularly built for easy service, and the compact design means a lighter weight and smaller pump compartment and features the same durable MagnaTrans™ gearbox as our popular LDM pump.

The PS Series pump has been the choice of thousands of departments around the world – confidence you can count on.

Industry’s Longest Warranty

- 10-year manufacturer’s, 10-year parts and 3-year labor